-

Máquina de proceso de goma

-

Máquina de goma del molino de mezcla

-

Cadena de producción de goma del polvo

-

Máquina de goma de la amasadora

-

Mezclador de goma de Banbury

-

Prensa de vulcanización de goma

-

Línea de goma reclamada de la hoja

-

Línea de reciclaje de plástico

-

pelota de tenis que hace la máquina

-

Amoladora de goma Machine

-

Lote de la máquina de enfriamiento de goma

-

Cadena de producción de goma de la banda transportadora

-

Máquina de goma del calendario

-

extrusora de doble esguince

-

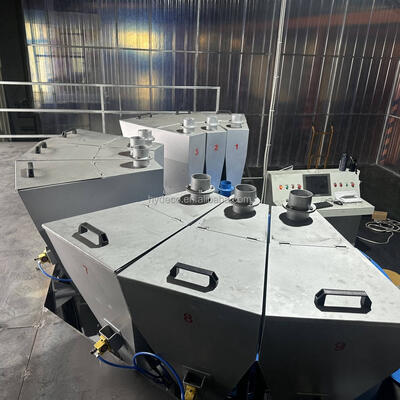

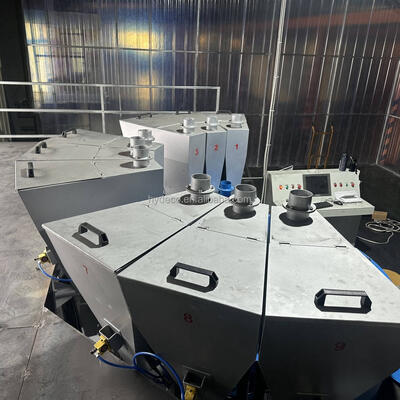

Sistema de pesaje automático circular para materiales pequeños

-

Sistema automático de pesaje de materiales pequeños

Sistema de pesaje automático de material tipo disco Máquina de procesamiento de caucho Máquina de dosificación

| Tipo | Máquina dosificadora de productos químicos | vídeo-inspección-saliente | Proporcionó |

|---|---|---|---|

| informe de prueba de maquinaria | Proporcionó | Componentes principales | PLC, motor, rodamiento, caja de cambios, motor, recipiente a presión, engranaje, bomba |

| Tipo de la máquina del neumático | Vulcanizador para formar neumáticos | Voltaje | 380 voltios |

| Dimensión (largo* ancho* alto) | 5m*5m*2m | Garantía | 1 año |

| Puntos clave de venta | Automático, Multifuncional, Precio competitivo, Alta Precisión, Alto Nivel de Seguridad, Ahorro de E | Potencia (kilovatios) | 30 |

| peso (kg) | 1000 | Producto final | Productos de caucho |

| Materia prima | SS304 | Función | Peso automático |

| Palabra clave | Pesaje automático, dosificación de productos químicos, sistema de pesaje de materiales pequeños | Producto final | Neumático de motocicleta, neumático, junta tórica de caucho, cámara, productos de caucho |

| Ventaja | Alta eficacia que produce | Capacidad | 15 toneladas |

| Estructura de máquinas | Estructuras de marco modernas | Característica | Eficiente y ecológico |

| Sistema de control | PLC+pantalla táctil | Cantidad mínima de pedido | 1 juego |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

El Hydecosiempre se adhiere a la orientación al cliente, siguió la filosofía empresarial de "integridad, ganar-ganar e innovación",con el objetivo de "crear productos de alta calidad" y el propósito de "satisfacción del cliente" para proporcionar a cada cliente una solución técnica rentable.La serie de productos ha logrado una combinación mutua de diseño estándar y no estándar.La calidad y el servicio de los productos han alcanzado el nivel internacional.

![]()

![]()

![]()

¿Es el sistema automático de pesaje de materiales pequeños adecuado para la industria del caucho?

Sí, está adaptado a la industria del caucho, centrándose en las necesidades de pesaje y batería de materiales pequeños en la producción de caucho.

¿Cuáles son las características principales de este sistema de pesaje?

Apoya el pesaje simultáneo a escala única o múltiple, el loteado de alta precisión, la selección automática de estaciones de trabajo y el tratamiento centralizado del polvo.También tiene una pequeña huella y bajos requisitos de mantenimiento.

¿Cómo garantiza el sistema una alta precisión de pesaje?

Su unidad de pesaje adopta una escala de diseño independiente de plataforma y la línea de transporte está completamente separada.Esto no sólo garantiza la precisión, sino que también acorta el tiempo de autoestabilización de pesaje y prolonga la vida útil de la escala de plataforma.

¿Qué tipos de alimentadores utiliza el sistema, y cómo ajustar la alimentación?

Está equipado con dos tipos de alimentadores: alimentadores de vibración electromagnética y alimentadores en espiral. Puede ajustar la amplitud y la frecuencia para cambiar entre velocidades de alimentación altas, medianas y bajas,equilibrando el ciclo de lote más corto y la mayor precisión.

¿Puede instalarse el sistema en talleres comunes?

Sí, se puede instalar en edificios de fábrica de una sola planta. Utiliza una plataforma de estructura de acero con dispositivos de eliminación de polvo de desempaque y alimentación incorporados para manejar el polvo de pesaje y desempaque.

¿Qué funciones de control tiene el sistema?

Adopta el control de la red informática, soportando la gestión de fórmulas en el lugar y a distancia, los datos

los informes, la gestión de los planes, las estadísticas de materiales y el bloqueo de alarmas.

¿Es fácil ampliar el sistema para futuras necesidades?

Sí, sus dispositivos de pesaje y transporte están en disposición lineal, y las unidades de pesaje se pueden ensamblar

de forma flexible, haciendo que la expansión sea fácil.